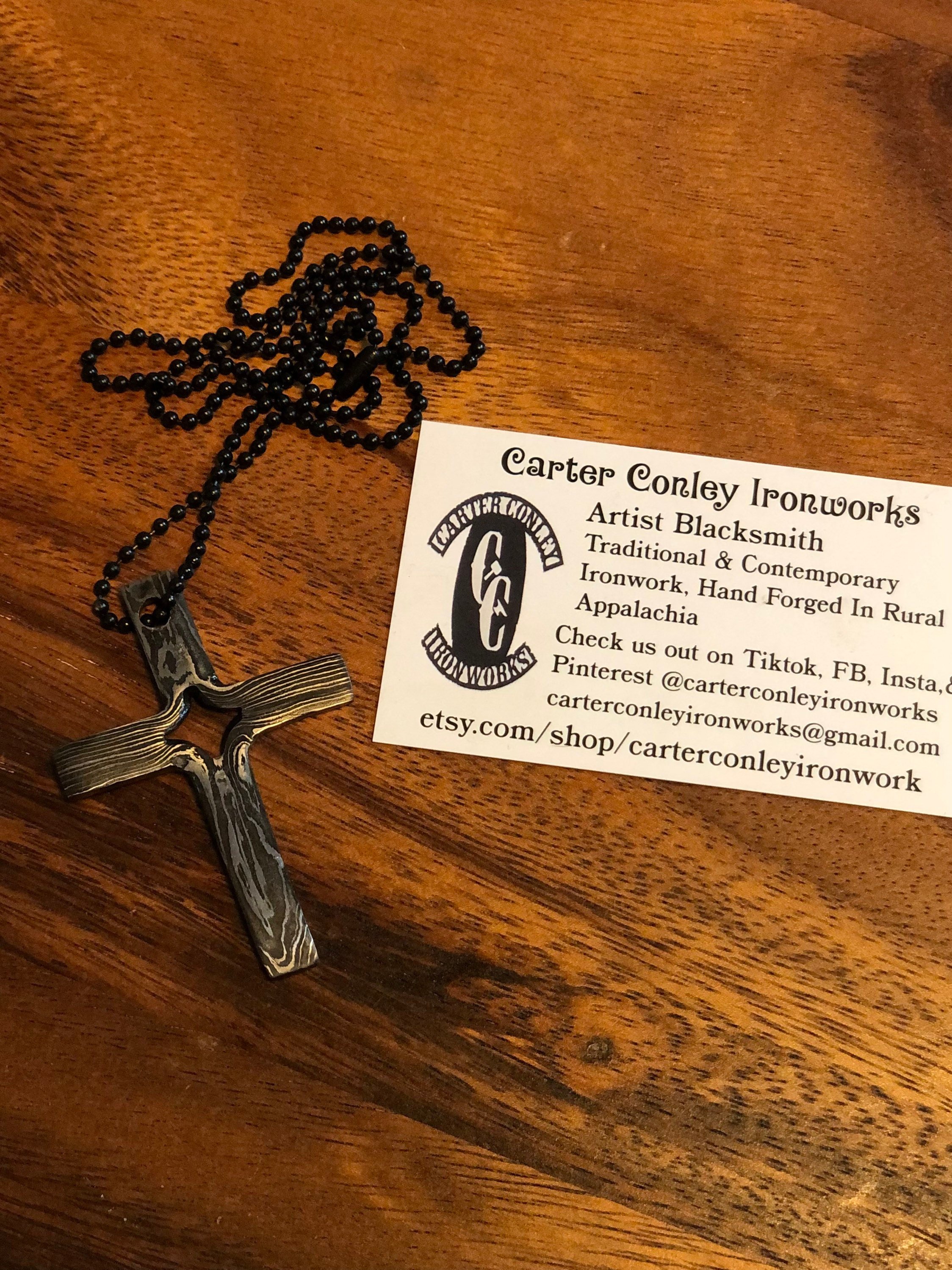

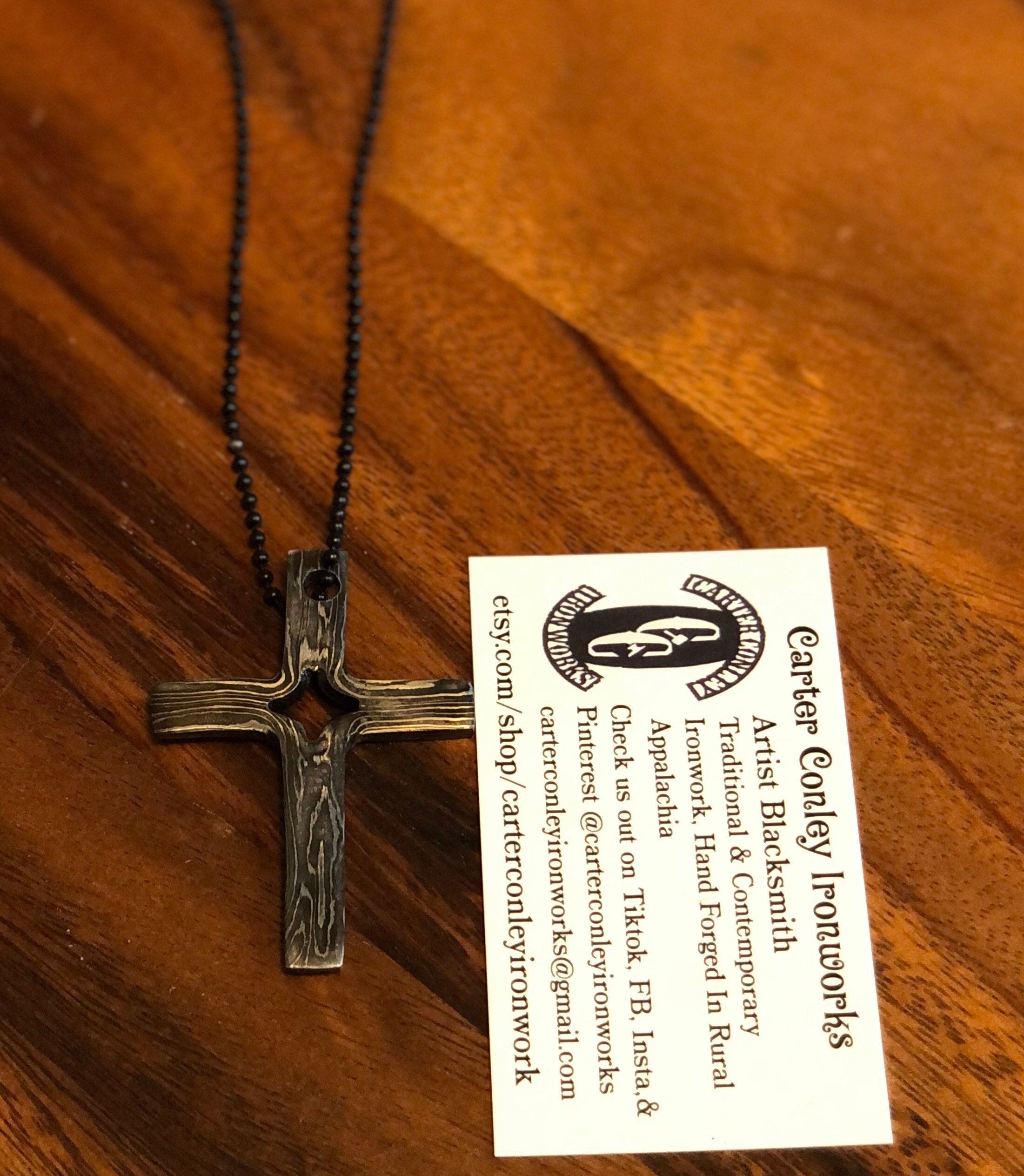

Damascus Steel Split Cross Necklace Forged to Finish Wearable Art

$139.99

These beautiful Damascus Cross necklaces are individually hand forged in rural Appalachia. The dimensions may vary slightly, but they average 2.5”-3” long and 2-2.5” wide.Pattern welded steel or “Damascus” steel as it is typically called today , consist of taking multiple layers of contrasting steels and forge welding them together until they a solid piece of steel then manipulating that new bar of steel in some way to achieve a pattern. These Necklaces start out as a 9-14 layer stack of alternating 1084 and 15N20 steel. After several forge welding heats the billet is then drawn out into roughly 3/8” square bar. Now that the material is ready, the cross itself is ready to be forged. This style of cross known as a split cross or Frederick’s cross, is made by making intersecting cuts down opposite sides of a bar of steel, the cuts or “splits” are then unfolded and flattened to create the arms and legs of the cross. After the cross is forged it is then ready for hand sanding and heat treat. (although it is unnecessary for ornamental items heat treating brings out the pattern more so I opt to heat treat). The crosses are hand sanded to 600 grit before and after heat treat. The last step consist of several rounds of etching, more hand sanding and finally a coffee “etch” to darken the dark steel while leaving the nickel steel shiny. Thanks for checking out my blacksmith shop! Carter Conley

These beautiful Damascus Cross necklaces are individually hand forged in rural Appalachia. The dimensions may vary slightly, but they average 2.5”-3” long and 2-2.5” wide.Pattern welded steel or “Damascus” steel as it is typically called today , consist of taking multiple layers of contrasting steels and forge welding them together until they a solid piece of steel then manipulating that new bar of steel in some way to achieve a pattern. These Necklaces start out as a 9-14 layer stack of alternating 1084 and 15N20 steel. After several forge welding heats the billet is then drawn out into roughly 3/8” square bar. Now that the material is ready, the cross itself is ready to be forged. This style of cross known as a split cross or Frederick’s cross, is made by making intersecting cuts down opposite sides of a bar of steel, the cuts or “splits” are then unfolded and flattened to create the arms and legs of the cross. After the cross is forged it is then ready for hand sanding and heat treat. (although it is unnecessary for ornamental items heat treating brings out the pattern more so I opt to heat treat). The crosses are hand sanded to 600 grit before and after heat treat. The last step consist of several rounds of etching, more hand sanding and finally a coffee “etch” to darken the dark steel while leaving the nickel steel shiny. Thanks for checking out my blacksmith shop! Carter Conley

These beautiful Damascus Cross necklaces are individually hand forged in rural Appalachia. The dimensions may vary slightly, but they average 2.5”-3” long and 2-2.5” wide.Pattern welded steel or “Damascus” steel as it is typically called today , consist of taking multiple layers of contrasting steels and forge welding them together until they a solid piece of steel then manipulating that new bar of steel in some way to achieve a pattern. These Necklaces start out as a 9-14 layer stack of alternating 1084 and 15N20 steel. After several forge welding heats the billet is then drawn out into roughly 3/8” square bar. Now that the material is ready, the cross itself is ready to be forged. This style of cross known as a split cross or Frederick’s cross, is made by making intersecting cuts down opposite sides of a bar of steel, the cuts or “splits” are then unfolded and flattened to create the arms and legs of the cross. After the cross is forged it is then ready for hand sanding and heat treat. (although it is unnecessary for ornamental items heat treating brings out the pattern more so I opt to heat treat). The crosses are hand sanded to 600 grit before and after heat treat. The last step consist of several rounds of etching, more hand sanding and finally a coffee “etch” to darken the dark steel while leaving the nickel steel shiny. Thanks for checking out my blacksmith shop! Carter Conley